1. Types of Foundation Brakes

The brake-assembly components at the wheels of a vehicle are generally called the foundation components because they form the basis on which the rest of the system is built. Foundation components are the mechanical parts contained in or around the wheels that are operated by the air brake system. An air brake system can be designed to work with several designs of foundation brake subsystems — even on the same vehicle.

There are three types of foundation brake systems — “S” cam brakes, Disc Brakes and Wedge Brakes.

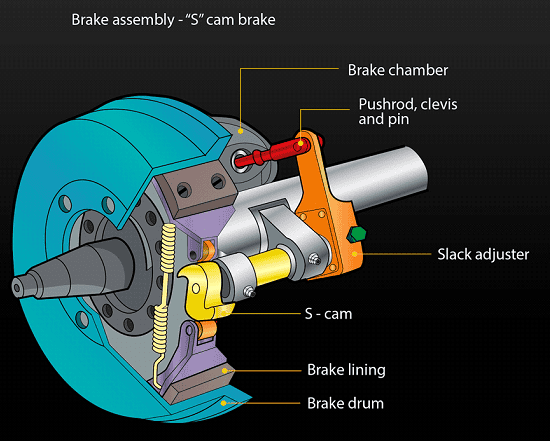

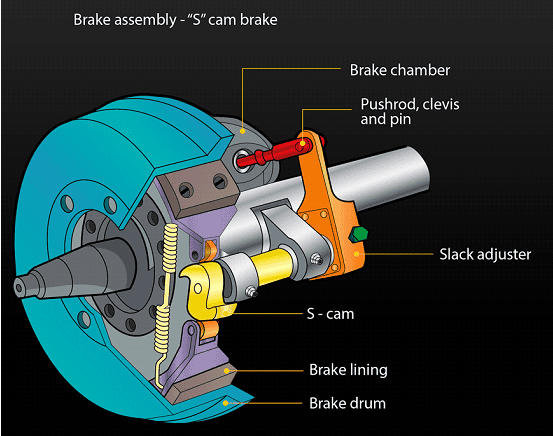

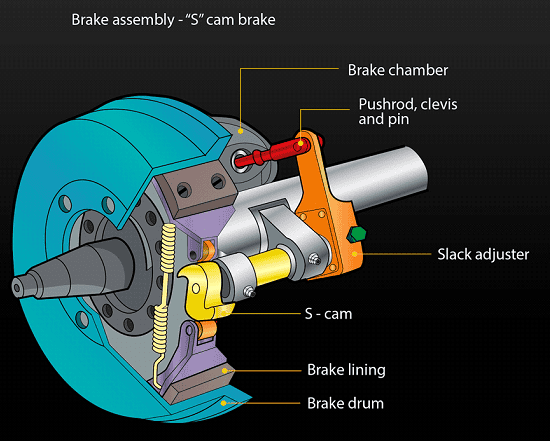

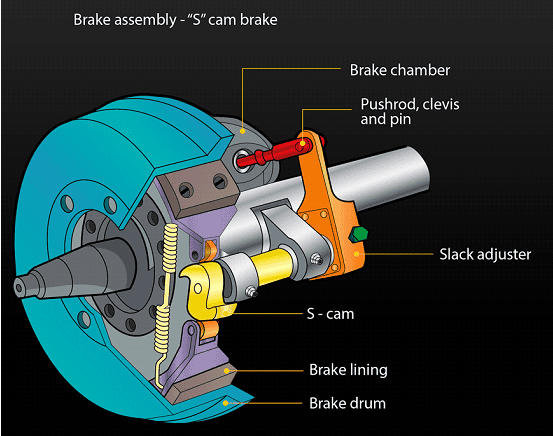

‘S’ Cam Brake

The ‘S’ cam brakes are the most common type of foundation brake used on commercial vehicles with air brake systems due to their reliability and effectiveness in heavy-duty applications.

Brake Type: S cam brakes are drum brakes, meaning they utilize a rotating drum and stationary brake shoes to create friction and stop the vehicle.

1. How S Cam Brakes Work:

- Air Brake Chambers: When the driver presses the brake pedal, air pressure is sent to the air brake chambers, which contain a diaphragm. The air pressure moves the diaphragm, which in turn moves the pushrod.

- Pushrod and Slack Adjuster: The movement of the pushrod acts on the slack adjuster, a lever connected to the camshaft. This movement causes the camshaft to rotate.

- Camshaft Mechanism: The camshaft has an “S” shaped cam at one end. As the camshaft rotates, the “S” cam shape pushes the brake shoes outward.

- Brake Shoes and Drum: The brake shoes press against the inner surface of the brake drum, creating friction. This friction slows down and eventually stops the wheel.

2. Key Features of S Cam Brakes:

- Exposed Pushrod: One distinctive feature of S cam brakes is the exposed pushrod, which allows for easy visual inspection and adjustment of the brake linkage.

- Component Protection: While the pushrod is exposed, many other components within the wheel assembly, such as the camshaft and brake shoes, are often protected by dust shields or backing plates to prevent debris contamination.

3. Advantages of S Cam Brakes:

- Durability: S cam brakes are known for their durability and ability to handle the high demands of commercial vehicle operations.

- Ease of Maintenance: The design allows for straightforward inspection and adjustment, which helps maintain optimal braking performance.

- Effective Braking: The mechanical advantage provided by the S cam shape ensures efficient force distribution, resulting in powerful and consistent braking action.

2. Components of S Cam Brakes

Introduction to S Cam Brake Components:

- Overview: The S cam brake system consists of several key components that work together to ensure efficient and reliable braking. Understanding each component’s role is essential for maintaining and troubleshooting the brake system.

Drums:

- Description: Brake drums are large, cylindrical components that rotate with the wheel. The inner surface of the drum provides a friction surface for the brake shoes.

- Function: When the brake shoes press against the drum, friction is generated, which slows down or stops the vehicle.

- Material: Typically made of cast iron for durability and heat dissipation.

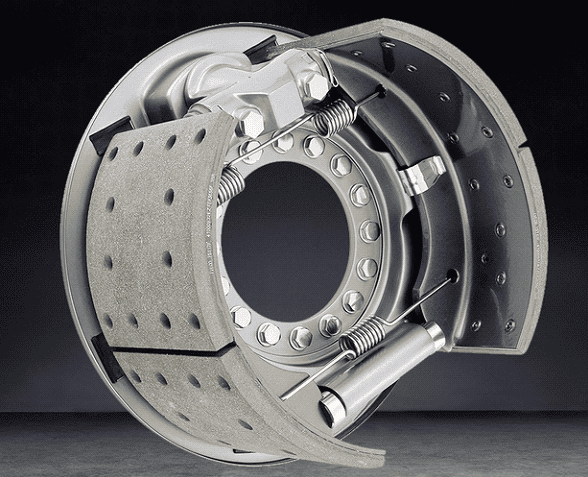

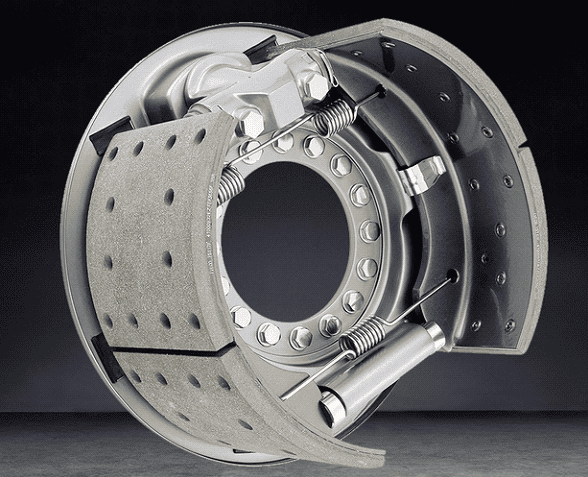

Shoes and Linings:

- Description: Brake shoes are curved metal plates with friction material (linings) attached to them.

- Function: The shoes press against the inner surface of the drum to create friction and stop the vehicle. The linings provide a friction surface and are designed to withstand high temperatures and wear.

- Replacement: Brake linings wear down over time and need to be periodically replaced.

-

Camshafts:

- Description: The camshaft is a metal rod with an “S” shaped cam at one end.

- Function: When the camshaft rotates, the “S” cam pushes the brake shoes outward, forcing them against the drum. This rotation is powered by the air brake system through the pushrod and slack adjuster.

Pushrods:

- Description: Pushrods are metal rods that connect the air brake chambers to the slack adjusters.

- Function: When air pressure is applied to the brake chamber, the pushrod extends, transferring force to the slack adjuster and rotating the camshaft.

Cam Support Brackets:

- Description: These brackets support the camshaft and keep it in place within the brake assembly.

- Function: Provide a stable pivot point for the camshaft to rotate, ensuring consistent and effective braking.

Spiders:

- Description: The spider is a central mounting bracket that holds various components of the brake assembly in place.

- Function: It provides the structural support for the brake shoes, camshaft, and other related components.

Rollers:

- Description: Rollers are cylindrical components that sit between the camshaft and the brake shoes.

- Function: They transfer the rotational force of the camshaft into linear motion, pushing the brake shoes outward against the drum.

Return Springs:

- Description: These are strong, tensioned springs connected to the brake shoes.

- Function: Return springs pull the brake shoes back to their original position when the brake pressure is released, ensuring the shoes do not drag against the drum.

Dust Shields and Backing Plates:

- Description: Dust shields and backing plates are protective covers located behind the brake assembly.

- Function: They protect the brake components from dirt, debris, and moisture, which can cause wear and reduce braking efficiency.

Slack Adjusters:

- Description: Slack adjusters are mechanical links that connect the pushrod to the camshaft.

- Function: They transfer the force from the pushrod to the camshaft and allow for manual or automatic adjustment of the brake shoe clearance to compensate for wear.

Brake Chambers:

- Description: Brake chambers are air-activated components that house a diaphragm and pushrod.

- Function: When air pressure is applied, the diaphragm pushes the pushrod out, initiating the braking process. They convert air pressure into mechanical force.

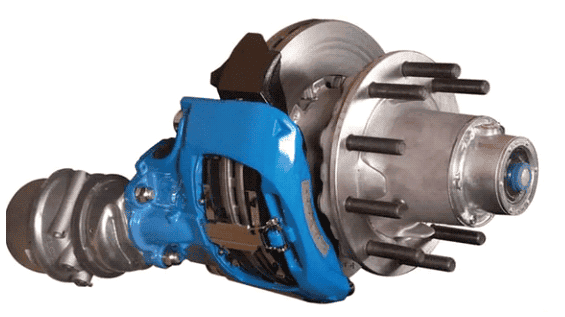

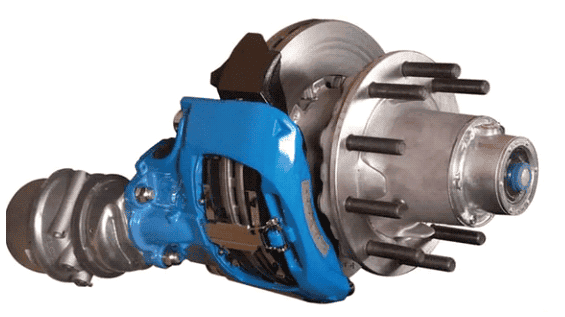

3. Disc Brakes and Their Components

Introduction to Disc Brakes:

- Overview: Disc brakes are a type of foundation brake commonly used in both commercial and passenger vehicles. They are known for their efficient braking performance and better heat dissipation compared to drum brakes.

- How They Work: Disc brakes use a caliper to squeeze pairs of pads against a disc or rotor to create friction, which slows down the rotation of the wheel. This braking action is more consistent and less prone to fading than drum brakes, making them ideal for a variety of applications.

Explanation of Disc Brakes:

- Functionality: When the brake pedal is pressed, hydraulic or pneumatic pressure is applied to the brake caliper. The caliper then squeezes the brake pads against the rotor, creating friction that slows the wheel’s rotation.

- Components Interaction: The main components of a disc brake system work together seamlessly to provide efficient and reliable braking. Each component has a specific role that contributes to the overall functionality of the brake system.

Components of Disc Brakes:

Rotors:

- Description: Rotors are flat, circular discs that rotate with the wheel.

- Function: When the brake pads clamp onto the rotor, friction is created, which slows down or stops the wheel.

- Material: Typically made of cast iron or composite materials to withstand high temperatures and wear.

Callipers:

- Description: Callipers are the components that house the brake pads and pistons.

- Function: They squeeze the brake pads against the rotor to create friction when activated by hydraulic or pneumatic pressure.

- Types: There are two main types of calipers: floating (or sliding) calipers and fixed calipers. Floating calipers move in and out relative to the rotor, while fixed calipers have pistons on both sides of the rotor.

Pads:

- Description: Brake pads are flat components with a friction material attached to one side.

- Function: The pads press against the rotor to create friction and slow the vehicle. The friction material is designed to wear down over time and is replaceable.

- Variety: Pads can be made from various materials, including organic, metallic, or ceramic, each offering different performance characteristics.

Slack Adjusters:

- Description: In air disc brakes, slack adjusters are mechanical links that connect the brake chamber to the caliper.

- Function: They adjust the travel distance of the brake pads to ensure they are always at the optimal position for braking.

- Adjustment: Slack adjusters can be manually adjusted or may have automatic adjustment mechanisms to compensate for wear in the brake pads and linings.

- Description: Brake chambers convert air pressure into mechanical force.

- Function: When air pressure is applied to the chamber, it pushes a diaphragm, which in turn moves a pushrod that applies force to the slack adjuster and ultimately to the caliper.

- Types: There are different types of brake chambers, including service chambers for normal braking and emergency/parking chambers for holding the vehicle stationary.

4. Wedge Brakes and Their Components

Introduction to Wedge Brakes:

- Overview: Wedge brakes are a type of drum brake system used in various commercial vehicles. They are known for their unique wedge mechanism, which applies braking force differently compared to S cam and disc brakes.

- How They Work: In wedge brakes, air pressure activates the brake chambers. The pushrod from the brake chamber drives a wedge between the brake shoes, forcing them outward against the brake drum. This action creates the friction needed to slow down or stop the vehicle.

Explanation of Wedge Brakes:

- Mechanism: The defining feature of wedge brakes is the wedge mechanism. When air pressure is applied, the brake chamber’s pushrod slides a wedge between the brake shoes, pushing them apart.

- Air Brake Chambers: Air brake chambers in wedge brakes are mounted so that their pushrods face inward toward the brake shoes and drum, ensuring a direct and efficient force application.

- Self-Adjusting Design: Wedge air brakes are designed to be self-adjusting, which helps maintain optimal brake performance and reduces the need for frequent manual adjustments.

- No Exposed Linkage: Unlike S cam brakes, wedge brakes do not have exposed brake linkage, which can help protect the components from environmental contaminants.

Components of Wedge Brakes:

Drums:

- Description: Brake drums are cylindrical components that rotate with the wheel. The inner surface of the drum provides the friction surface for the brake shoes.

- Function: When the brake shoes are forced outward by the wedge mechanism, they press against the drum, creating friction that slows down or stops the vehicle.

Shoes and Linings:

- Description: Brake shoes are curved metal plates with friction material (linings) attached to them.

- Function: The shoes press against the inner surface of the drum to create friction. The linings provide the friction surface and are designed to withstand high temperatures and wear.

- Replacement: Brake linings wear down over time and need to be periodically replaced to maintain effective braking.

Spiders:

- Description: The spider is a central mounting bracket that holds various components of the brake assembly in place.

- Function: It provides structural support for the brake shoes, wedge mechanism, and other related components.

Dust Shields:

- Description: Dust shields are protective covers located behind the brake assembly.

- Function: They protect the brake components from dirt, debris, and moisture, which can cause wear and reduce braking efficiency. Dust shields help maintain the longevity and performance of the brake system.

Brake Chambers:

- Description: Brake chambers are air-activated components that house a diaphragm and pushrod.

- Function: When air pressure is applied to the chamber, it pushes a diaphragm that moves a pushrod. This pushrod then drives the wedge mechanism, forcing the brake shoes outward against the drum.

- Types: There are different types of brake chambers, including service chambers for normal braking and emergency/parking chambers for holding the vehicle stationary.