1. Trailer Brake Components

The trailer brake system is a complex network of components that work together to ensure the trailer can be safely and effectively stopped. Understanding each component and its role is essential for anyone operating or maintaining trailers.

Each component plays a specific role in ensuring the trailer’s brakes function correctly and safely. As we progress through the module, we will explore each component in more detail, discussing their functions and how they interact with the rest of the system.

Trailer Brake Components:

These are the essential parts that form the backbone of the trailer brake system. They include the brake chambers, brake shoes, and brake drums. These components are responsible for converting the energy from compressed air into the mechanical force needed to stop the trailer.

Connecting a Trailer:

Connecting the trailer to the towing vehicle is a crucial step in ensuring the brake system functions correctly. This process involves securing the trailer hitch and ensuring all connections, particularly the air brake lines, are properly attached. A secure connection is vital for safe operation.

Trailer Couplers or “Gladhands”:

Gladhands are specialized couplers used to connect the air brake systems between the trailer and the towing vehicle. They are typically color-coded (red for emergency lines and blue for service lines) to prevent incorrect connections, which could lead to brake malfunction. Properly connected gladhands ensure that air can flow between the two systems, allowing the brakes to function.

Applying Trailer Service Brakes:

Trailer service brakes are applied using the trailer hand valve or foot valve, allowing the driver to control the trailer’s brakes independently of the towing vehicle’s brakes. This capability is particularly useful for controlling the trailer’s movement on downhill slopes or during emergencies.

Trailer Supply Valve:

The trailer supply valve controls the air supply to the trailer’s brake system. It ensures that the trailer has sufficient air pressure to operate the brakes effectively. When the trailer is disconnected, this valve shuts off the air supply to prevent air loss from the towing vehicle.

Tractor (Towing Vehicle) Protection Valve:

This valve is designed to protect the towing vehicle’s air supply in the event of a trailer breakaway or severe air leak. It prevents the loss of air pressure in the towing vehicle, ensuring that it can still operate safely even if the trailer’s air system fails.

Automatic Spring (Parking and Emergency) Brakes:

These brakes automatically engage when the air pressure drops below a certain level (typically 414 kPa or 60 psi). They act as a fail-safe mechanism to prevent the trailer from moving unintentionally. Spring brakes are used for both parking and emergency situations, providing a reliable way to secure the trailer when not in use.

Spring Brake or Service Brake Priority:

In some systems, air is prioritized to release the spring (parking) brakes before applying the service brakes. This ensures that the trailer can be moved even if there is an issue with the service brake air supply. This priority system helps maintain control and safety during various operating conditions.

2. Connecting a Trailer

Properly connecting a trailer to the towing vehicle is a critical step that ensures the functionality and safety of the trailer brake system. The connection process involves several precise steps that must be followed carefully to prevent brake system malfunctions and ensure secure attachment.

Steps to Connect a Trailer:

Align the Trailer with the Towing Vehicle:

- Begin by positioning the towing vehicle and trailer in a straight line. This alignment is essential to ensure a secure and stable connection.

- Use mirrors and, if necessary, have a spotter guide you to achieve proper alignment.

- The trailer should be at the same height as the towing vehicle’s hitch to facilitate an easy connection.

Secure the Trailer Hitch:

- Once aligned, lower the trailer hitch onto the towing vehicle’s ball mount or fifth wheel.

- Ensure the hitch is fully seated and locked in place. This might involve engaging a locking mechanism or securing a latch, depending on the type of hitch used.

- Double-check the connection by visually inspecting it and attempting to move the trailer slightly to ensure it is securely attached.

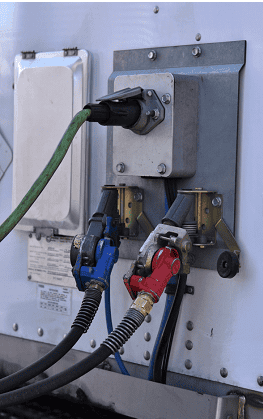

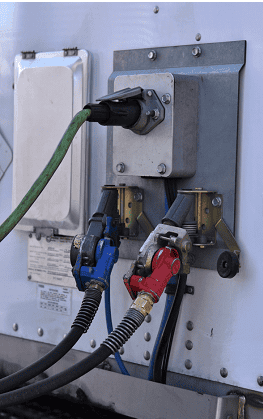

Connect the Trailer Couplers (Gladhands):

- Trailer couplers, also known as “gladhands,” are specialized connectors used to join the air brake systems of the trailer and towing vehicle.

- Typically, gladhands are color-coded to prevent incorrect connections. The red gladhand connects to the emergency line, and the blue gladhand connects to the service line.

- Firmly press the gladhands together and twist them to lock them in place, ensuring a secure and airtight connection.

- Check for any signs of wear or damage on the gladhands and replace them if necessary to prevent air leaks.

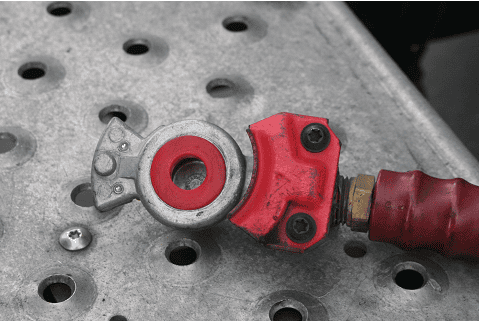

3. Trailer Couplers or Gladhands

Trailer couplers, commonly referred to as “gladhands,” are essential components in the air brake system of trailers and towing vehicles. These couplers serve as the critical link that allows the air brake systems of the trailer and towing vehicle to function as a single, integrated unit.

Trailer Couplers or “Gladhands”:

Purpose and Function:

- Gladhands are specialized connectors designed to join the air brake systems of a trailer and its towing vehicle.

- They facilitate the transfer of compressed air from the towing vehicle to the trailer, ensuring that the trailer’s brakes can be applied simultaneously and effectively with the towing vehicle’s brakes.

Color-Coding for Safety:

- To prevent incorrect connections, gladhands are typically color-coded. This color-coding is a safety measure designed to ensure that the correct air lines are connected.

- The red gladhand usually connects to the emergency air line, which supplies air to the trailer’s emergency brake system.

- The blue gladhand typically connects to the service air line, which supplies air to the trailer’s service brakes.

- This color-coding helps operators quickly and easily identify the correct connections, reducing the risk of cross-connection, which can lead to brake system malfunctions.

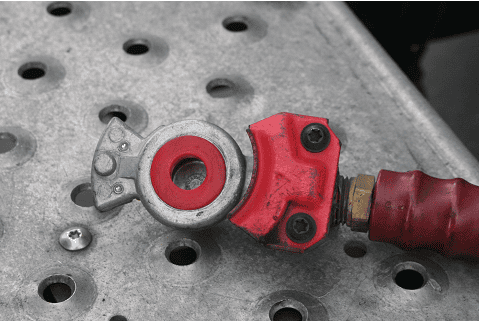

Proper Connection to Avoid Malfunction:

Ensuring that gladhands are properly connected is crucial for the safe operation of the air brake system.

When connecting gladhands, press them firmly together and twist them to lock into place, creating a secure and airtight connection.

A secure connection prevents air leaks, which can compromise the effectiveness of the brake system.

Before setting off, always perform a visual inspection and a tug test to confirm that the gladhands are properly connected and locked.

Importance of Proper Use:

Using gladhands correctly is essential for maintaining the integrity and functionality of the trailer’s brake system. An improper connection can lead to several issues, including:

- Air Leaks: Which can reduce air pressure in the brake system, leading to reduced braking power and potentially causing brake failure.

- Brake Malfunctions: Incorrectly connected gladhands can result in the trailer brakes not engaging properly, posing a significant safety risk.

- Safety Hazards: Inadequate braking power can lead to accidents, especially in emergency situations where effective braking is critical.

4. Trailer Brake Shut-off Valves

A towing vehicle can pull more than one trailer by using additional supply and service connectors at the rear of each trailer. These connectors must be identical to those used on the towing vehicle to ensure compatibility and seamless operation of the air brake system across all trailers. When connecting multiple trailers, the supply and service lines extend from the towing vehicle to the first trailer and then from each trailer to the next. This setup allows the compressed air from the towing vehicle to flow through all connected trailers, ensuring their brakes function properly.

To prevent air loss from the supply and service lines when they are not in use, these lines are typically equipped with manual shut-off valves. These valves can be closed to seal off the air lines, maintaining the necessary air pressure within the brake system and preventing any potential leaks. It is crucial for drivers to be familiar with the operation of these manual shut-off valves, as improper use can lead to a loss of air pressure, compromising the brake system’s effectiveness and safety.

Operating a towing vehicle with multiple trailers requires a thorough understanding of the additional components and their proper usage. Drivers must be well-versed in the correct procedures for connecting and disconnecting trailers, managing air lines, and using shut-off valves. Proper training and familiarity with these aspects are essential to ensure safe and efficient operation, prevent air loss, and maintain the integrity of the brake system across all connected trailers.

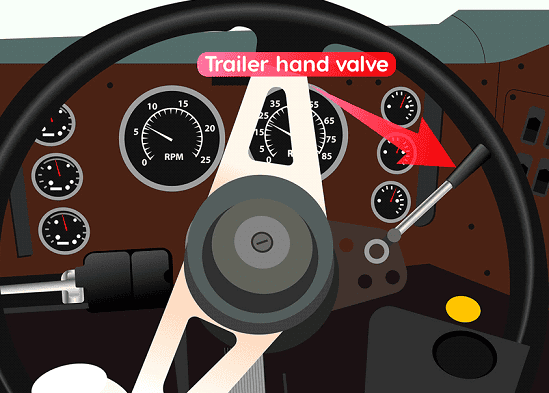

5. Applying Trailer Service Brakes

Applying the trailer service brakes is a critical function that allows drivers to control the braking of the trailer independently from the towing vehicle. This capability is essential for maintaining safety and stability, especially in various driving conditions such as descending steep slopes, making tight turns, or during emergency stops. The primary mechanism for applying the trailer service brakes independently is the trailer hand valve.

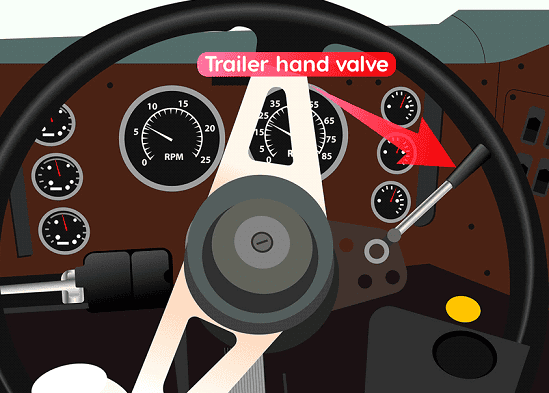

Trailer Hand Valve:

The trailer hand valve, sometimes referred to as the “trolley valve” or “Johnson bar,” is a manual control located within the driver’s reach in the cab of the towing vehicle. It is specifically designed to apply the trailer’s service brakes without engaging the brakes on the towing vehicle. This feature provides several key benefits:

Independent Control:

- By using the trailer hand valve, the driver can apply the trailer’s brakes independently of the towing vehicle’s brakes. This independent control is crucial in situations where the trailer needs to be slowed down or stopped without affecting the towing vehicle.

- For example, when descending a steep hill, the driver can use the trailer hand valve to apply the trailer brakes, helping to maintain control and prevent the trailer from pushing against the towing vehicle.

Stability and Safety:

- Independent control of the trailer brakes enhances overall vehicle stability. During turns, particularly sharp ones, the ability to apply only the trailer brakes can help keep the trailer aligned with the towing vehicle, reducing the risk of jackknifing or skidding.

- In emergency situations, such as when the trailer begins to sway or fishtail, the driver can use the trailer hand valve to bring the trailer back under control without overloading the towing vehicle’s brakes.

Controlled Stopping:

- Using the trailer hand valve allows for more controlled and gradual stopping of the trailer. This controlled braking is especially useful when maneuvering in tight spaces or when precision is required, such as in docking or parking scenarios.

Operation and Best Practices:

To use the trailer hand valve effectively, drivers should follow these best practices:

- Familiarity: Ensure you are familiar with the location and operation of the trailer hand valve before driving. Practice using the valve in safe, controlled environments to understand its responsiveness.

- Gradual Application: Apply the trailer brakes gradually using the hand valve to avoid sudden stops that could destabilize the trailer or towing vehicle.

- Regular Maintenance: Regularly inspect and maintain the trailer hand valve and associated components to ensure they are in good working condition. Proper maintenance helps prevent malfunctions that could impair braking performance.

6. Trailer Supply Valve

The trailer supply valve is an essential component in the air brake system of a trailer, designed to control the flow of air from the towing vehicle to the trailer’s brake system. This valve is typically located near the driver’s seat within easy reach and is characterized by a red, eight-sided knob. Its design and functionality are critical for the safe and efficient operation of both the trailer’s service and emergency brakes.

Operation and Function:

Air Supply Control:

- The trailer supply valve manages the air supply to the trailer’s brake system through the supply line. When the driver pushes the red, eight-sided knob in, the valve opens, allowing compressed air to flow from the towing vehicle’s air tanks into the trailer’s air tanks. This air is then used to operate the trailer’s brakes.

- To close the valve, the driver pulls the knob out, which stops the air supply to the trailer. This action is necessary when no trailer is attached to prevent unnecessary air loss from the towing vehicle’s brake system.

Automatic Closure to Prevent Air Loss:

- A crucial feature of the trailer supply valve is its ability to close automatically in the event of a significant drop in air pressure or when no trailer is connected. This automatic closure mechanism activates when the air pressure in the trailer supply line falls between 20 and 45 psi (138 and 311 kPa).

- This design helps prevent a large amount of air from escaping the towing vehicle’s air brake system, which could otherwise lead to a dangerous reduction in braking power.

Pressure Dynamics and Safety Mechanisms:

- When the valve is open and the air begins to escape, the pressure in the trailer supply line drops much faster than the pressure in the towing vehicle’s air tanks. Because of this rapid pressure loss, the trailer supply valve typically closes automatically well before the pressure gauge in the cab reads between 20 and 45 psi. This feature ensures that the air supply is cut off quickly, preserving the necessary air pressure in the towing vehicle’s system.

- The automatic closure of the trailer supply valve is particularly important in scenarios where the trailer may become detached from the towing vehicle. In such cases, the rapid loss of pressure triggers the valve to close, preventing the complete depletion of air from the towing vehicle’s air brake system.

Emergency Braking Functionality:

- In addition to controlling the air supply, the trailer supply valve also plays a vital role in emergency braking situations. If the trailer’s service brakes fail, the driver can use the trailer supply valve to apply the trailer’s spring brakes. By pulling the knob out, the driver can engage the spring brakes, which are designed to activate when there is a loss of air pressure, bringing the trailer to a safe stop.

- This emergency functionality provides a critical backup braking mechanism, enhancing overall safety and ensuring that the trailer can be stopped even if the primary braking system is compromised.

Importance of the Trailer Supply Valve:

- Safety: The trailer supply valve is integral to maintaining the safety and integrity of the trailer’s braking system. Its ability to control the air supply and automatically close to prevent air loss ensures that the brakes remain functional and effective.

- Operational Efficiency: Proper use of the trailer supply valve ensures that the trailer’s brakes are always ready for use, whether in normal driving conditions or emergency situations. Regular checks and maintenance of this valve are crucial for ensuring its reliability and performance.

- Driver Responsibility: Drivers must be familiar with the operation of the trailer supply valve, understand how to use it properly, and recognize the signs of potential issues. This knowledge is essential for preventing accidents and ensuring the safe operation of the vehicle.

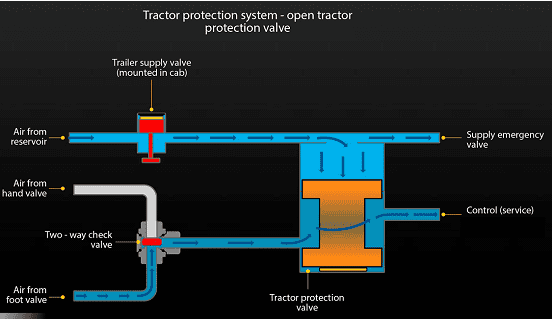

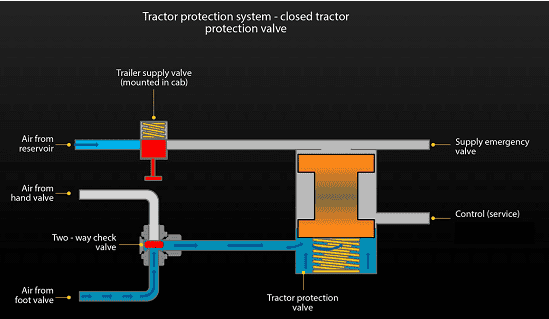

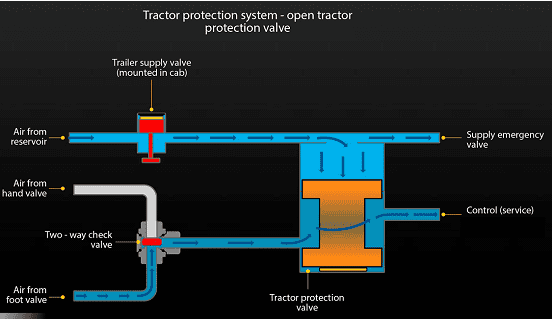

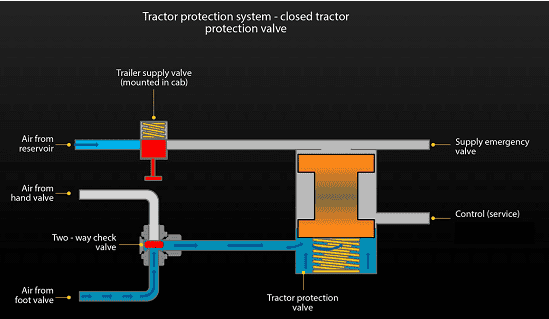

7. Tractor (Towing Vehicle) Protection Valve

The tractor protection valve is a vital component in the air brake system of a towing vehicle, designed to safeguard the vehicle’s air supply by preventing air loss when no trailer is attached. This valve works in conjunction with the trailer supply valve to ensure the integrity and functionality of the towing vehicle’s braking system.

Function and Operation:

Coordination with the Trailer Supply Valve:

- The operation of the tractor protection valve is directly controlled by the trailer supply valve. When the trailer supply valve is closed, the tractor protection valve also closes, preventing air loss from the towing vehicle’s air system.

- When the trailer supply valve is opened to supply air to the trailer, air pressure is also directed to open the tractor protection valve. This allows air to flow through the valve and into the trailer service line, enabling the trailer’s brake system to function.

Preventing Air Loss:

- The primary purpose of the tractor protection valve is to prevent air from escaping the towing vehicle’s air system when there is no trailer attached. This is critical for maintaining sufficient air pressure in the towing vehicle’s brake system, ensuring it remains operational and safe.

- When the trailer supply valve is closed, air pressure exhausts from the tractor protection valve, causing it to close by spring force. This closure prevents any air from passing through the valve, effectively sealing off the air supply and preventing unnecessary air loss.

Automatic Closing Mechanism:

- The tractor protection valve closes automatically when the air pressure from the trailer supply valve is exhausted. This automatic closing mechanism is activated by spring force, ensuring the valve closes promptly and securely.

- When the tractor protection valve is closed, air can still enter the valve, but it does not pass through to the trailer service line. This means that even if the towing vehicle’s air tanks are pressurized, no air will be lost through an unattached trailer line, preserving the towing vehicle’s brake system pressure.

Maintaining Brake System Integrity:

- By preventing air loss, the tractor protection valve plays a crucial role in maintaining the integrity of the towing vehicle’s air brake system. It ensures that the vehicle retains sufficient air pressure to operate its own brakes effectively, even when a trailer is not connected.

- This valve is essential for the safe operation of the towing vehicle, as it helps prevent situations where the vehicle’s brake system could be compromised due to air loss through unattached trailer lines.

Operational Sequence:

Opening the Trailer Supply Valve:

- When the driver pushes in the trailer supply valve, air pressure is directed to both the trailer’s air system and the tractor protection valve.

- The increased air pressure opens the tractor protection valve, allowing air to flow through it and into the trailer service line, enabling the trailer’s brakes to function.

Closing the Trailer Supply Valve:

- When the driver pulls out the trailer supply valve, air pressure is exhausted from the tractor protection valve.

- The reduction in air pressure causes the tractor protection valve to close automatically by spring force, sealing off the air supply and preventing air loss from the towing vehicle’s system.

8. Automatic Spring (Parking and Emergency) Brakes

Automatic spring brakes, also known as parking and emergency brakes, are a critical component of the trailer brake subsystem. These brakes are designed to engage automatically when the air pressure in the trailer’s supply line falls below a certain threshold, ensuring the trailer remains stationary or can be stopped safely in case of an emergency.

Functionality of Automatic Spring Brakes:

Service Brakes vs. Spring Brakes:

- The trailer brake system employs two types of brakes: service brakes and spring brakes.

- Service Brakes: Used for regular braking during normal driving conditions, these brakes are applied by the driver using the brake pedal. They rely on air pressure to function.

- Spring Brakes: Serve as both parking and emergency brakes. Unlike service brakes, spring brakes use mechanical force from compressed springs to engage the brakes when air pressure drops.

Automatic Engagement:

- Spring brakes are designed to apply automatically when the air pressure in the trailer supply line drops below 60 psi (414 kPa). This automatic engagement is a safety feature that ensures the trailer remains stationary or can be brought to a stop even if there is a failure in the air brake system.

- When the air pressure is sufficient (above 60 psi), the compressed air holds back the spring force, keeping the brakes released. When the pressure drops, the springs expand, engaging the brakes.

Reasons for Air Pressure Drop:

- Parking the Vehicle: When the driver parks the vehicle and pulls out the trailer supply valve, the air pressure in the trailer supply line is intentionally released. This action causes the air pressure to drop below 60 psi, automatically engaging the spring brakes to secure the trailer and prevent it from moving.

- Supply Line Rupture or Disconnection: If the trailer supply line ruptures or becomes disconnected, the air pressure in the supply line will drop rapidly. This sudden loss of pressure will trigger the spring brakes to apply automatically, stopping the trailer to prevent uncontrolled movement.

Importance of Automatic Spring Brakes:

Safety Mechanism:

- Automatic spring brakes provide a fail-safe mechanism to ensure the trailer is securely parked or brought to a stop in emergencies. This feature is crucial for preventing accidents caused by trailer rollaway or brake system failures.

- By engaging automatically when air pressure drops, spring brakes help maintain control over the trailer even in situations where the service brakes may not be operational.

Reliability:

- The reliance on mechanical spring force, rather than air pressure, makes spring brakes highly reliable. They do not depend on the air brake system’s integrity to function, providing an additional layer of safety.

- This reliability is especially important in emergency scenarios, such as a trailer breakaway, where immediate braking is necessary to prevent accidents.

Regulatory Compliance:

- The automatic engagement of spring brakes when air pressure drops below 60 psi is a regulatory requirement in many regions, ensuring that trailers meet safety standards for both parking and emergency braking.

Operation and Maintenance:

- Regular Inspections: Regularly inspect the spring brake components for wear and damage. Ensure that the springs are in good condition and that the brake chambers are functioning correctly.

- Proper Training: Drivers should be properly trained on the operation and function of spring brakes. They should understand how to test the spring brakes and recognize signs of potential issues.

- System Checks: Perform regular system checks to ensure that the trailer supply valve and air lines are in good working order. Any signs of air leaks or pressure drops should be addressed immediately to maintain the effectiveness of the spring brakes.

9. Spring Brake or Service Brake Priority

In trailer brake subsystems, the distribution of air pressure to the brakes can follow different priority systems: spring brake priority or service brake priority. This prioritization affects the sequence and safety of brake engagement, impacting the overall operation of the trailer’s braking system.

Spring Brake Priority:

Functionality:

- In a system with “spring brake priority,” the air from the towing vehicle first fills the air tank for the spring brakes to a certain pressure before filling the air tank for the service brakes.

- This ensures that the spring brakes are released first, allowing the trailer to be towed immediately, even before the service brake air tanks are fully pressurized.

Advantages:

- Trailers with spring brake priority can be moved quickly as the spring brakes are released first, providing immediate mobility.

- This setup is beneficial in situations where quick movement of the trailer is necessary, such as in busy freight yards or emergency relocations.

Potential Risks:

- One significant risk is that a trailer could be on the road without sufficient air pressure to operate its service brakes. This could lead to a dangerous situation where the driver has reduced braking capability.

- If there is air loss to the service brakes, the spring brakes in many modern systems will begin to apply as they lose air, but there may still be a period where the trailer is vulnerable due to insufficient service brake pressure.

Service Brake Priority:

Functionality:

- In trailers with “service brake priority,” the air from the towing vehicle first fills the air tank for the service brakes before filling the air tank for the spring brakes.

- This ensures that the service brakes are fully operational before the spring brakes are released, providing full braking capability before the trailer can be moved.

Advantages:

- This system ensures that there is always sufficient air pressure to operate the service brakes before the trailer is towed, enhancing safety.

- It eliminates the risk of towing a trailer with insufficient air pressure for the service brakes, ensuring that full braking capability is available from the outset.

Operational Safety:

- Service brake priority systems ensure that the trailer’s service brakes are always ready for use, reducing the risk of accidents caused by inadequate braking pressure.

- This system is particularly advantageous in regular road use, where consistent and reliable braking is critical for safety.

Handling Air Loss:

- Spring Brake Priority Systems:

- If there is a loss of air to the trailer service brakes, the spring brakes may remain released while the service brakes are unavailable. This creates a potential hazard where the trailer lacks adequate braking.

- The only way to apply the brakes in such a scenario is to close the trailer supply valve, causing the spring brakes to apply automatically due to the loss of air pressure.

Consultation and Best Practices:

- It is crucial for drivers to understand which priority system their trailer uses. Consulting with an employer or a qualified person can help determine whether a trailer operates on a spring brake or service brake priority system.

- Proper knowledge of the system ensures that drivers can take appropriate actions in case of air loss or other emergencies, maintaining safety and operational efficiency.

Summary:

- Spring Brake Priority: Air fills spring brake tanks first; trailer can be moved quickly but may lack service brake pressure initially.

- Service Brake Priority: Air fills service brake tanks first; ensures full braking capability before movement, enhancing safety.